Thread Manufacturer Rebuilds Old Machinery for Efficient Operations

/Kreinik Manufacturing Company continues to invent new ways to breathe new life into old machinery at a family-owned facility. Kreinik maintenance engineer relies on creative craftsmanship to improve efficiency and reliability.

By Michelle Segrest, Navigate Content, Inc. — Reporting for Maintenance Technology Magazine

If Martin Ankrom has a super power, it is breathing new life into old equipment. Similar to how he keeps his 1950 Ford pickup truck running like new, he finds a way to resuscitate old machinery every day as the maintenance engineer at Kreinik Manufacturing Co. Inc., in Parkersburg, West Virginia.

“If you have the ability to look inside the equipment and see that it’s jammed, or old, or deviated, there is always a way to fix it,” Ankrom said. “You can never give up on it or it will beat you.”

Ankrom works like a modern-day Dr. Frankenstein. He throws nothing away and has a large warehouse full of spare parts from microwaves, old motors, broken computers, and even pencil sharpeners. It’s his “Spare Parts Mall,” and he goes shopping every day.

“I found three motors in an old broken-down microwave and realized that each one could be used for various equipment in our facility,” he said. “The motor that turns the plate inside the microwave has 1.5 horsepower. This is absolutely wonderful for powering some of our equipment. Whenever computers break down around here, I harvest them like a carnivore. They have great little compact fans that can cool other equipment. There are so many different little switches, lights, and toggles that people just toss away because we live in such a disposable society. That’s a shame. If it’s done being one thing it can become something else.”

Ankrom uses this creative craftsmanship to keep operations running at the 7,500-sq.-ft. Kreinik facility. Jerry and Estelle Kreinik started the family-owned business in their home in the early 1970s. Estelle was a needleworker who basically wanted access to more interesting threads. The couple started researching, buying, and then making them.

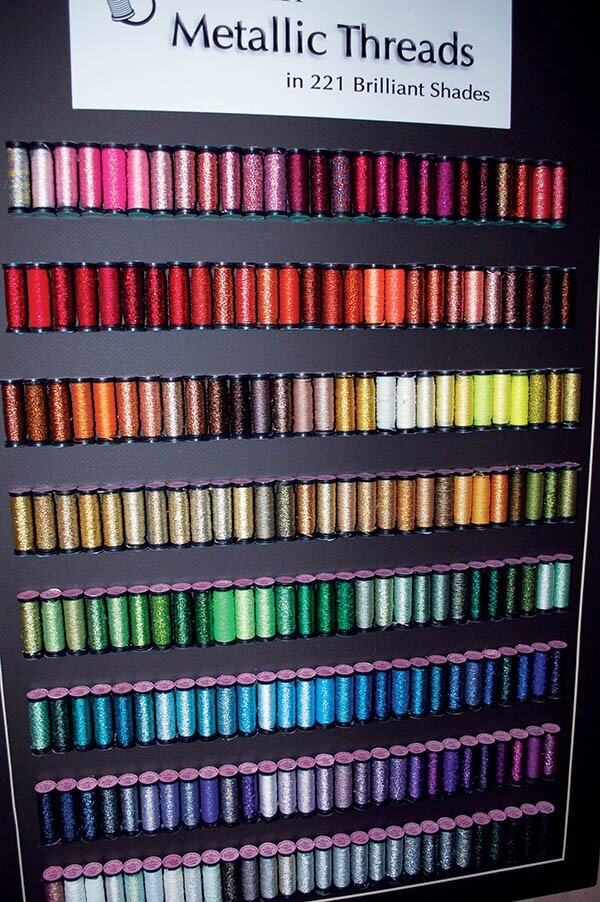

The inventor of the D-Ring for the Department of the Navy, Jerry had a knack for creating ideas and building them. The couple invented the first thread organizer and then peddled this and other products door-to-door to build the company’s foundation. Today, Kreinik Manufacturing makes a variety of silk and metallic threads for needleworkers, crafters, scrapbookers, quilters, fiber artists, fly fishermen—even fashion houses—to help them express their creative selves. “We pretty much always have thread on the brain,” said company president Doug Kreinik, son of Jerry and Estelle. “It’s how we look at the world.”

The operation has grown significantly since Doug Kreinik joined the family business in 1983. At that time, there were 10 braiding machines, and now there are more than 130. With only 17 employees, the facility also uses winding, coning, skeining, and card-winding and packaging machines to produce more than a million spools each year.

Kreinik and Ankrom continue the company’s tradition—borne of the mother of invention—by inventing solutions each day to keep the operations running with extremely old equipment in a very tight space.

“We have a philosophy that if you can find the right parts, you can make the stuff you need,” Kreinik said. “Every piece of equipment you see was made by someone. It didn’t just pop out of a tree. I worked for a while as a computer programmer and carried with me the philosophy that if you can think it, you can code it. It’s the same with our equipment. We know how to re-invent it and keep it running.”

Kreinik believes that “small is big” and that there is still room for creativity in manufacturing.

“We can find a way to put something together,” he said. “It may not be beautiful or look like it’s supposed to, but it’s going to function. We make old things new again with good maintenance. For example, Martin is taking apart and rebuilding one of our machines. He is simplifying it and making it easier to use and is using fewer parts. He is taking something that was broken and actually improving it to make it run more efficiently than ever.”

But this kind of creative manufacturing also requires a contingency plan, Ankrom explained. “If something goes down, there is always a backup to keep things running while I fix it,” he explained. “I have worked with engineers who have the mindset of Fred Flintstone. It works like this, and it’s worked like this for 50 years. This is the way we are going to keep on going. But being a wrench jockey, I always ask questions and make efforts to try something new. I look at how the design can be changed to bring down waste and build profit. The thought process of simply buying something new is just using your wallet and not using your mind.”

Efficient Manufacturing Best Practices

With an old-school approach to modern technology, Doug Kreinik still uses white boards and paper orders to track operations. This is a different definition of efficient manufacturing, he said.

“Our system is not sophisticated, but it works for us,” he explained. “We take raw material and break it down in 14 different ways. We would spend more time entering this into a computer than it takes to actually produce the products. We choose to keep it simple, and this just works for us. We have such customized products and have to operate with a certain kind of organized randomness. We look at ways to improve things, but always with the mindset of how we can make it simpler rather than more complicated.”

With this philosophy, Kreinik’s creative genes come in handy. “Growing up, I thought everyone’s parents were well educated and inventors,” Kreinik said. “When I got into the real world, it was an awakening. We keep things simple and creative. I’ve often thought that a boring job is a job where you can make mistakes. Make a boring job faster, and there is no time to make mistakes.”

Creative Engineering Best Practices in Thread Manufacturing

Ankrom makes work fun and creative by reverse-engineering the manufacturing equipment and rebuilding it to be something better than before.

“Martin’s task is to make our equipment more efficient and standardize them so we are always producing products,” Kreinik said. “He also finds ways to make operations more ergonomically sound and safer for the operators. Martin is always studying and reading manuals and making sure he has a precise understanding of how everything works from the inside out. Then he can get creative with ways to rebuild them with more efficiency.”

This philosophy is the norm at the company. “Our goal is the keep the machinery alive as long as possible,” Ankrom said. “When I came here in 2010, I was smitten with the idea of working with antique equipment. I had grown up around antiques and really tired old machines, cars, and motorcycles, and I love the challenge of bringing them back to life.”

Ankrom uses his experience as a fabricator, a machinist, an operator, and an engineer to make this happen. In a small facility, there are many intricate details that must be addressed to keep things running smoothly, he said.

“If I can’t find the right part, I make it,” he continued. “I then try to ‘Westernize’ the ancient European machines by modifying them in many creative ways. There is a methodology to taking things apart and putting them back together. What we do here is take complex machines and simplify them. It’s almost impossible to find some of these parts, so I eliminate that need by inventing and building new parts. We look at things outside the box and repurpose everything. I don’t let anyone throw anything away.”

When he’s not rebuilding equipment, Ankrom spends his time putting out fires and working on preventive maintenance. He has the help of a part-time employee, but it’s mostly a one-man team on the maintenance side. He must incorporate a strict routine to keep the operation running smoothly and efficiently.

“I come in each day and work with the operators to see what is needed,” he explained. “I have a stringent maintenance campaign to pay close attention to the compressors, as they’re vital to our operation to control the humidity and temperature. I go to every machine to make sure it is functioning just as it is supposed to before everyone else comes in to work.”

Ankrom also schedules blocked time for preventive and predictive maintenance. Serviceability is a key best practice.

“A small example is where motors were originally installed,” he said. “I have difficulty getting into them to service them. There is no reason for them to live in such an environment. I relocated them so they are raised to eye level and you don’t have to lay on your back to perform the maintenance.”

Planning and strategizing are also big parts of the overall atmosphere.

“You usually can’t just dive right into it,” Ankrom said. “We like to spend a little time thinking about creative ways we can make it better and more efficient. Another thing is consistency. The idea of making everything in the house the same is so easy. Instead of having multiple kinds of motors we just have one kind. This way, I can have the same brand of replacement parts throughout the house. If one machine goes down, you can take that product line off and put it on a different machine. And we document everything so that we have a detailed history of repairs.”

While it remains a family-owned company, Kreinik Manufacturing has changed significantly since its humble beginnings. It now produces many thread colors and sizes and distributes its products worldwide. It even provided the metallic threads for Queen Cersei’s gown in the opening scene of Season 7, Episode 1, of the Game of Thrones television series.

With a small facility that produces large quantities of product, reliability remains the core of the company’s operations.

“We must make sure that we continue to make things simpler and better,” Doug Kreinik concluded. “I come from a creative and imaginative background, and so does Martin. I might not understand everything, but I ask questions. And each day we use creative ideas and forward thinking to make things more efficient and more reliable.”

C.A.K.S. CHARITY

The C.A.K.S. charity project is a line of fashion-forward shoelaces, eyeglass strings, scissor/badge lanyards, and keyrings ("Keysters") made from Kreinik threads to benefit suicide prevention, grief counseling, and substance abuse programs. The idea came about as the Kreinik family was looking for a way to help others through a terrible loss: the suicide of a loved one (their son, Charles).

While the company no longer actively produces new stock, there is a selection available at its factory outlet store in Parkersburg, West Virginia. Pick up a pair in your favorite colors (school colors, or team colors, too) when you visit the plant. Choose from fun, colorful metallic or glow-in-the-dark shoelaces, high-end silk lanyards and eyeglass strings, and shiny metallic key holders.

Michelle Segrest is President of Navigate Content, Inc., a full-service content creation firm. She has been a journalist for more than three decades and specializes in covering the people and processes that make a difference in the industrial processing industries. Contact her at michelle@navigatecontent.com

Original version published in Maintenance Technology, December 2017. Updated December 2019.